Cable Cold Bending Test is a test method used to evaluate the flexibility and cold resistance of cables at low temperatures. The test is designed to simulate the application of cables in cold climates or cryogenic environments to ensure that cables retain their flexibility and mechanical properties at low temperatures without cracking or damage.The Cold Bend Test is performed according to IEC 60811-504 and is designed to evaluate the performance of cables at low temperatures. Samples of insulation and sheath material must be tested within 16 hours of completion of the extrusion or cross-linking process.

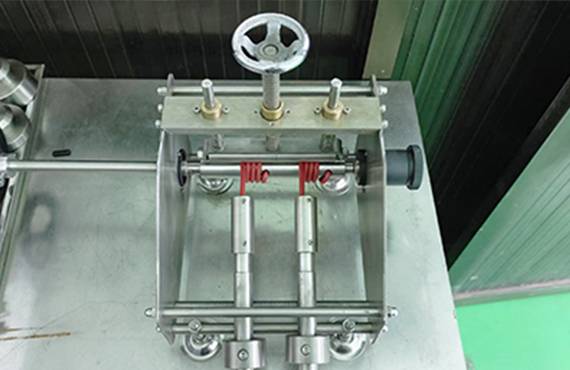

The test equipment needs to include a cryogenic chamber capable of maintaining the specified test temperature, typically used to simulate a low temperature environment. In addition, the test equipment needs to include bending equipment, as described in the IEC 60811-504 standard, to apply a specified bending strain. This bending equipment is used to simulate the bending of cables at low temperatures.

The test specimen shall normally be a length of cable and shall be of sufficient length to achieve a specified number of rotations around the mandre The nominal diameter of the mandrel shall be 4 to 5 times the nominal diameter of the test sample. These requirements ensure that proper bending and strain can be obtained in the sample during testing.

Before testing begins, the cable sample is clamped to the mandrel from the top. This step ensures that the sample is tightly attached to the mandrel during the test so that it can be subjected to a consistent force when a bending strain is applied.

After clamping the sample, the sample is placed in an appropriate test chamber and adjusted to a specific temperature. This step is done to bring the sample to equilibrium at the test temperature and usually takes at least 16 hours. In some cases, depending on the specific pre-cooling criteria, this conditioning time can be shortened.

Once the sample has reached equilibrium at the test temperature, the test sample is wound around a mandrel according to the number of turns specified in the IEC 60811-504 standard. This step simulates the bending strain that the cable may experience in a low temperature environment.

During testing, the test chamber is maintained at the same test temperature. This ensures that the entire test process is carried out under consistent temperature conditions to simulate cable performance in a low-temperature environment.