Conductors are typically soldered to contact points. Soldering not only ensures a secure electrical connection but also provides protection against oxidation at the conductor's contact points. Therefore, it is essential to conduct tests to ascertain the suitability of conductors for soldering, with test parameters established in accordance with IEC 60245-2. Initially, the exposed ends of the cable must be immersed in a pickling bath at ambient temperature, which contains a solution of zinc chloride and water (where ZnCl constitutes 10% of the total mass) for 10 seconds.

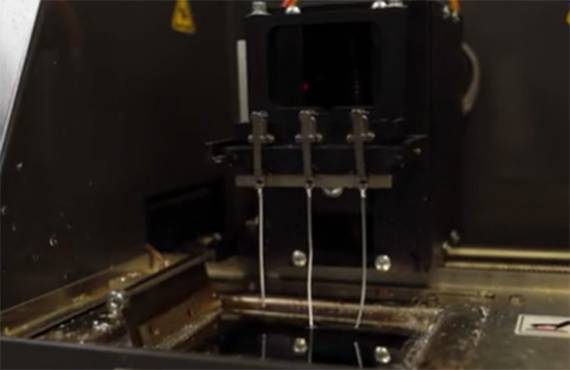

Subsequently, the test specimen is longitudinally immersed in a solder bath for a length of 50mm. The immersion speed is controlled at 25mm/s ± 5mm/s, and the immersion time in the solder bath is controlled at 5s ± 0.5s. Similarly, the withdrawal speed is maintained at 25mm/s ± 5mm/s.

To meet the testing requirements, a total of three immersions in the solder must be completed, with a continuous 10-second interval observed between the start of the first immersion in the solder bath and subsequent immersions.

The entire process strictly regulates the test temperature using a digital temperature controller. After three immersions, a visual inspection is conducted to determine whether the cable has been properly tinned, and the pass/fail status is determined accordingly.

For further information regarding cable solderability testing or to discuss supplementary cable accessories, please reach out to our technical experts.