The cables are expected to continue to operate and function in accordance with the relevant cable standards with a life cycle of up to 25 years. To ensure that long-term use does not negatively affect the cable, it is important to carry out tests after the accelerated ageing process.

Tensile testing of photovoltaic cables after ageing is a test method used to evaluate the tensile properties and durability of solar cables after a certain amount of ageing or exposure to environmental factors. This test is designed to simulate the mechanical stresses that solar cables may experience after prolonged use in outdoor environments to determine if the cables are still strong and resilient enough to meet their design and performance requirements.

Select a certain number of samples from actual production batches of solar cables. These samples should have the same material and construction as the solar cables used in the actual application.

Samples are often subjected to a certain ageing or exposure process to simulate use in outdoor conditions. This may include exposing the samples to UV radiation, high temperatures, high humidity or other environmental factors, depending on the purpose and criteria of the test.

The five test pieces specified in BS EN 60811-501 are hung substantially vertically in the centre of the oven to ensure that each test piece is at least 20 mm from any other test piece The test pieces shall be kept in the oven at the temperature and for the duration specified for the test material After the ageing period, they shall be removed and kept at ambient temperature away from direct sunlight for at least 16 hours. At the end of the ageing period, the test pieces shall be removed and placed at ambient temperature and protected from direct sunlight for at least 16 hours.

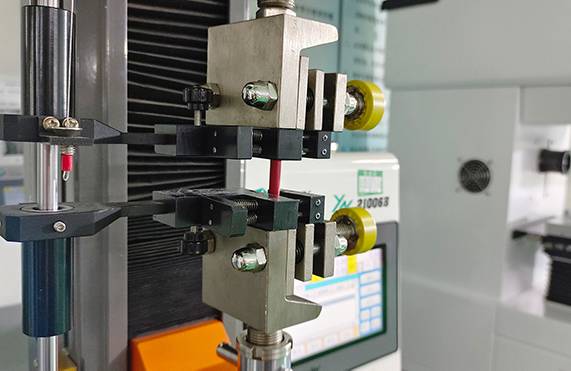

After the sample has undergone a certain amount of aging or exposure, the sample is placed in tensile test equipment. The test equipment applies a gradually increasing tensile force or strain to the sample to simulate the tensile stresses to which the cable may be subjected in actual use.

During tensile testing, the tensile strength, elongation, breaking point and other parameters related to the tensile properties of the samples are measured. These measurements are used to evaluate the durability and performance of the cable samples.

KUKA CABLE's solar cables have an ageing elongation of up to 185%, which exceeds the EN50618 standard.