Each photovoltaic module has two output wires, and each photovoltaic string has dozens of module wiring. How to manage the solar cable arrangement has become a more important issue. Normally, the positive, negative, and neutral wires of the cable are mixed in the bridge box, but the cable sheath may be worn, and the positive and negative wires may be short-circuited or electric field interference may occur. In addition, it is necessary to consider that the cable sheath may be bitten by rodents in the bridge box.

Trenching is often chosen when laying cables over long distances. Trenching is an engineering cost that cannot be ignored, and the site’s landfill and on-site walking safety must also be considered. If you want to rework or do cable inspections in the future, you will need to dig the ground again. Recently, a new photovoltaic power station solar cable construction management plan was applied for a patent in the United States, which is conducive to solving these problems.

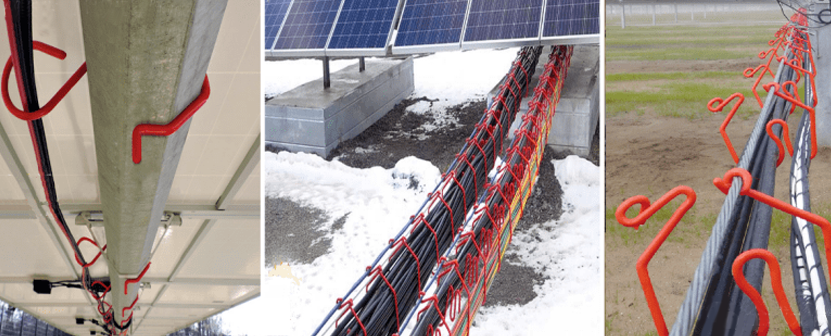

As can be seen from the above figure, this technology only uses a hanger with a simple design, bent into a certain shape, which is much simpler than cable trays, and more beautiful and more formal than cable ties.

The hanger can be directly hung on the photovoltaic support under the components with not too high voltage, and the other end can support the positive and negative cables of the components; in the cable connection between the arrays, because the voltage and current are already large, the different The polarized cables are separately placed in the hanger to separate different types of cables in different buckles; when many array cables are gathered together, the cables of different polarities can be placed in different hangers.

This kind of hanger design is quick and convenient to install, more cost-effective than trenching or cable troughing, and can save a lot of labor and materials for photovoltaic projects. The multi-snap hanger safely separates the cable bundle and meets NEC and other electrical requirements. The grounding function can also be integrated into the design at the same time.

The design surface of the hanger has a thick plastisol coating, which provides a firm grip between the hanger and the load-bearing cable, and prevents the hanger from sliding or moving during the life of the project. The wiring system is installed through high-strength load-bearing cables installed on the middle and end pier supports in the photovoltaic array. Then, each hanger is connected to the load-bearing cable at a preset interval. The cables are easy to load into the hanger and separate safely to meet NEC requirements.