The Tests

We work with customers in more than 120 locations around the world, however most of our customers do not have a good understanding of the basic construction, safety attributes and key features of cables, which leads to a tendency to choose cheaper products with numerous safety hazards, and we would like to pass on more knowledge about cable testing and inspection.

Stick to the quality bottom line

KUKA CABLE insists on inspecting the raw materials of the cables into the warehouse, conducting systematic tests on the electrical and mechanical properties of the ex-factory products, and delivering them only after they have passed the test, and issuing a conformity report to the customer.

Common test items in cables

The performance requirements vary from cable to cable, as well as the performance requirements and certification standards around the world, so having qualified laboratories and rigorous testing of raw materials and finished cables is the key to guaranteeing quality.

-

Cable Bend Test

Cable Bend Test -

The water resistance test

The water resistance test -

UV Accelerated Weather Testing for Cables

UV Accelerated Weather Testing for Cables -

Cable abrasion testing

Cable abrasion testing -

Cable Cold Bending Test

Cable Cold Bending Test -

Cold Elongation Testing for Cables

Cold Elongation Testing for Cables -

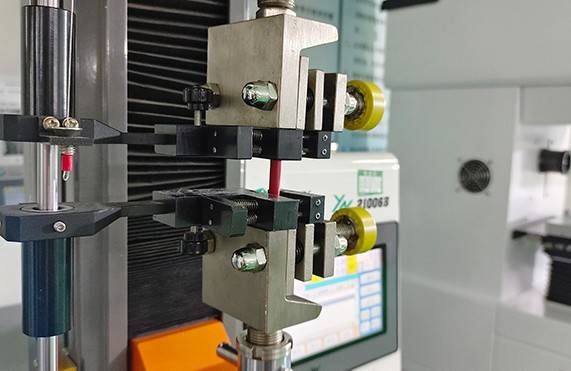

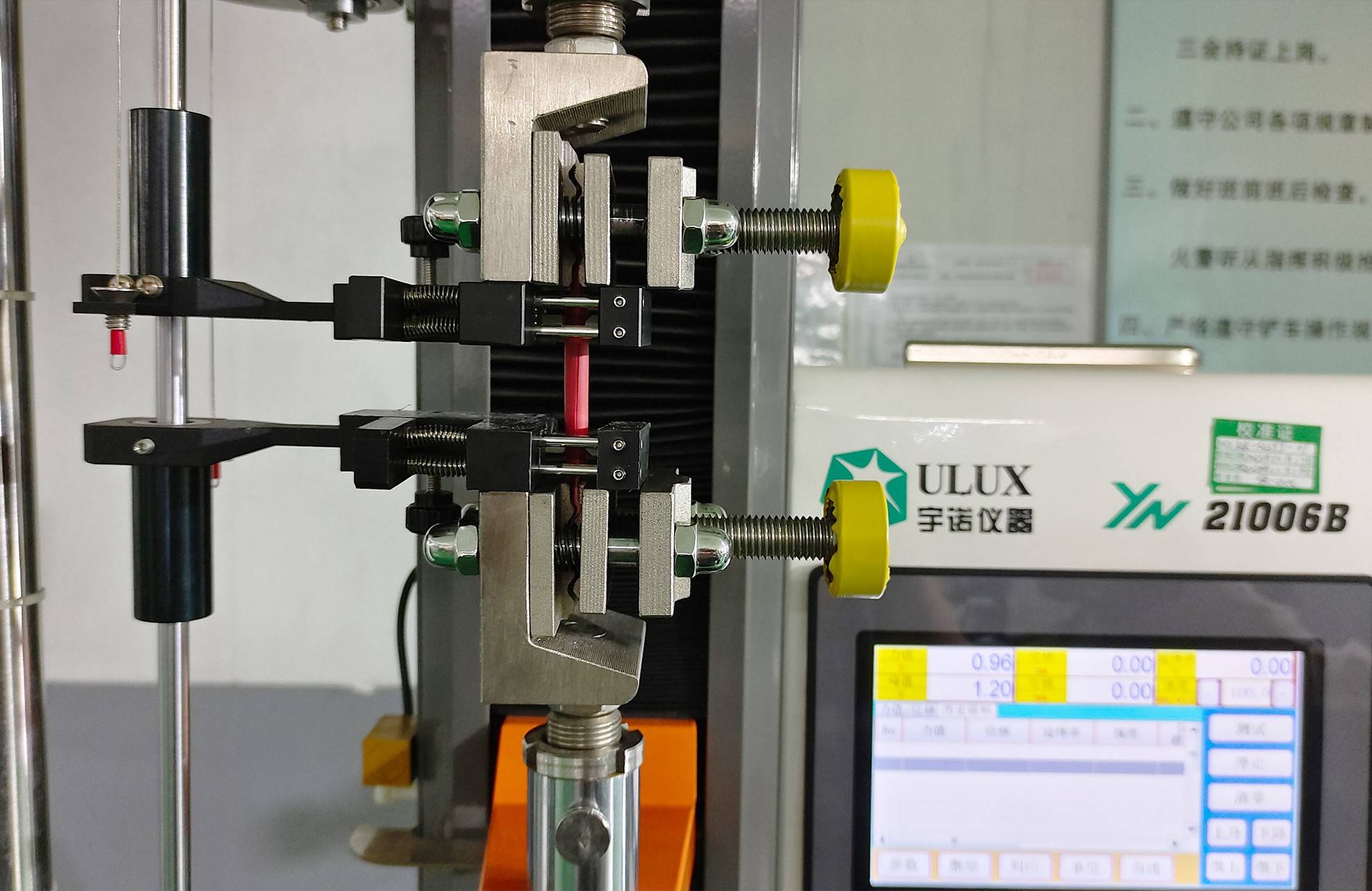

Cable Tensile Testing After Ageing

Cable Tensile Testing After Ageing -

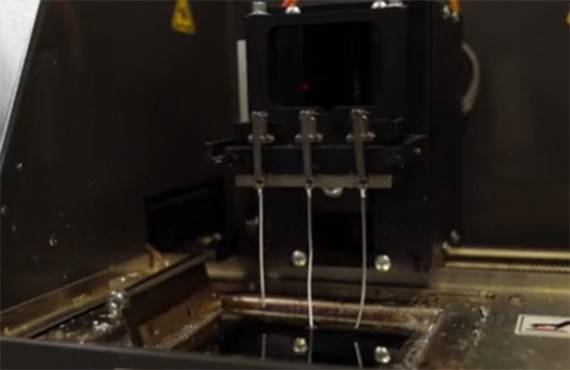

Cable Solderability Test

Cable Solderability Test -

Static Flexibility Testing of Cables

Static Flexibility Testing of Cables -

Cable Construction & Dimensional Testing

Cable Construction & Dimensional Testing -

Oil immersion testing of cables

Oil immersion testing of cables -

The ozone test

The ozone test